Rosemount 3051CG4A02A1KM5I1S5Q4Q8TTR Pressure Transmitter,

Rosemount 3051CG4A02A1KM5I1S5Q4Q8TTR Pressure Transmitter,

Couldn't load pickup availability

Secure checkout via Stripe & PayPal

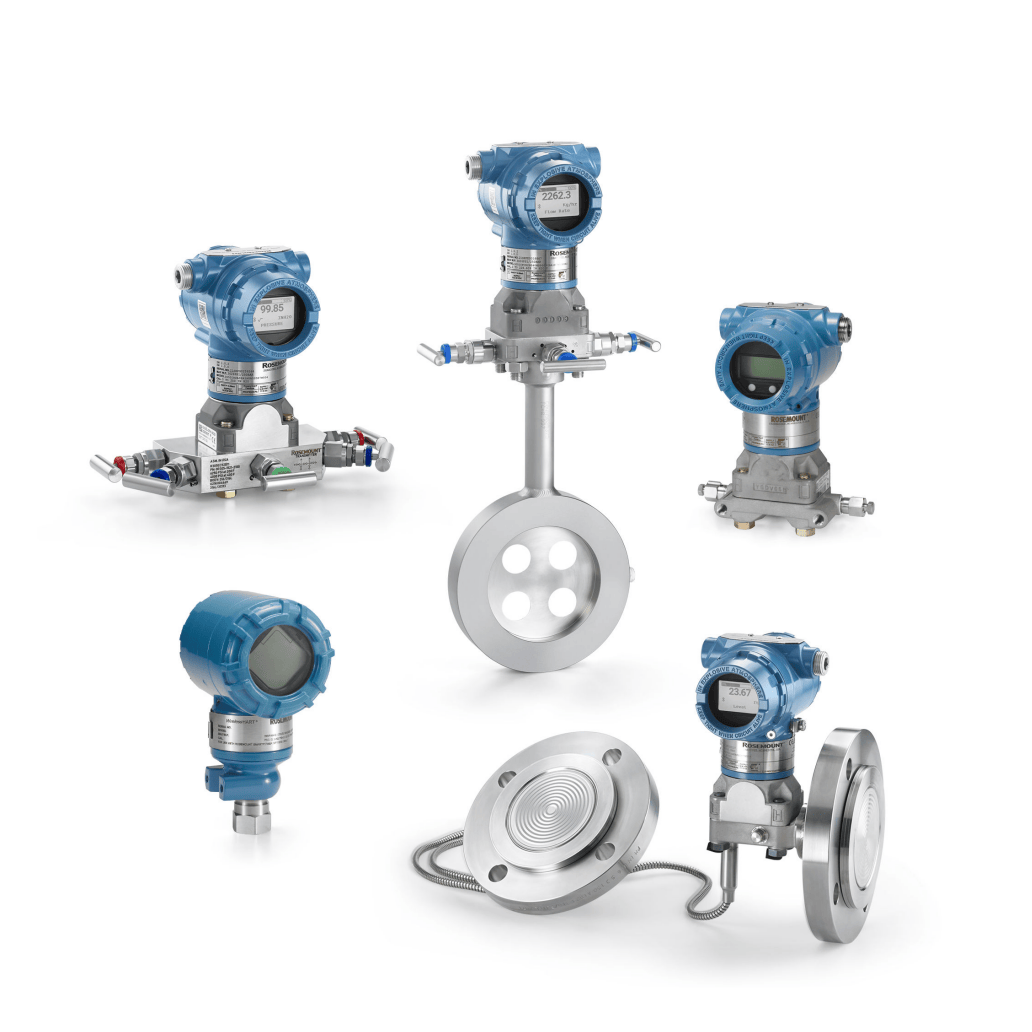

The 3051CG4A02A1KM5I1S5Q4Q8TTR is a gage-pressure transmitter in the proven 3051 C-series platform. It combines high accuracy, robust materials, advanced diagnostics, and modular flexibility to meet demanding industrial applications—from chemical processing and oil & gas to power generation and water treatment.

-

Measurement and Performance

• Measurement type: Gage pressure

• Range code 4: –14.2 to +300 psi (–0.97 to 20.68 bar)

• Reference accuracy: ±0.04 % of span (linearity, hysteresis, repeatability)

• Installed total performance: ±0.14 % of span over 0 – 100 % range, –40 to 185 °F, up to 3626 psig

• Long-term stability: 0.2 % of URL over 10 years (–40 to 185 °F, line pressures up to 1000 psig)

• Response time (4–20 mA/HART): <100 ms (transducer + electronics) -

Output and Communication

• Analog: Two-wire 4–20 mA with superimposed HART digital protocol

• HART features: Universal device description, advanced diagnostics, custom tags

• Optional FOUNDATION™ Fieldbus or PROFIBUS® PA versions (not in this model code)

• Optional wireless HART for cable-free configuration (not in this model code) -

Mechanical Design and Materials

• Coplanar “C” series platform allows direct mounting of integral manifolds and flow/level modules

• Process connection: “Alternate” coplanar flange for customer-supplied manifold or adapter

• Wetted materials:

– Isolating diaphragm: 316L stainless steel

– Secondary seal: Glass-filled PTFE O-ring

– Fill fluid: Silicone oil

• Housing: 316 stainless steel with M20 × 1.5 conduit entry

• Drain/vent ports: Stainless steel, factory-tested leak-tight -

Local Display and Configuration

• LCD display (two lines, up to eight characters per line) for process variable, units, diagnostics

• Push-button interface for local zero, span, configuration and diagnostics without opening the cover

• Optional graphical display (not in this model code) for multi-language menus and backlighting -

Safety and Certification

• Intrinsically safe certification (ATEX I 1) for hazardous locations

• SIL 2 capable with proof testing (optional) for safety-instrumented systems

• Optional explosion-proof, dust-ignition-proof, and worldwide approvals -

Integrated Manifold Assembly

• Code S5: Factory assembled to a three-valve integral manifold

• Benefits:

– One leak-tested assembly reduces field welding and fitting count

– Simplifies commissioning and maintenance

– Minimizes footprint and weight -

Calibration and Traceability

• Code Q4: NIST-traceable calibration certificate supplied with each transmitter

• Code Q8: Material traceability certificate per EN 10204 3.1 B for all pressure-wetted parts -

Additional Features and Options

• Transient protection (optional T1 terminal block) against electrical surges

• NACE MR0175/ISO 15156 compliance for sour service materials

• Optional remote-seal performance report (code QZ) to quantify overall system accuracy -

Environmental and Process Limits

• Ambient temperature: –40 to 185 °F (–40 to 85 °C)

• Process temperature (silicone fill): –40 to 250 °F (–40 to 121 °C) for coplanar flanges

• Overpressure limit: 4500 psig (310 bar) with static pressure option

• Static line pressure: 0.5 psia to 3626 psig (0.03 to 250 bar) -

Application Benefits

• High-accuracy gage measurement for pumps, compressors, filters, and vessels

• Coplanar design streamlines piping and reduces installation time

• HART diagnostics enable proactive maintenance and process optimization

• Robust stainless-steel construction and optional sour-service materials ensure reliable operation in harsh environments

Conclusion

The 3051CG4A02A1KM5I1S5Q4Q8TTR pressure transmitter delivers best-in-class gage-pressure performance in a versatile Coplanar package. Its combination of precision, diagnostics, integrated manifold assembly, and rigorous certifications make it ideal for critical industrial processes requiring both accuracy and reliability.

Share