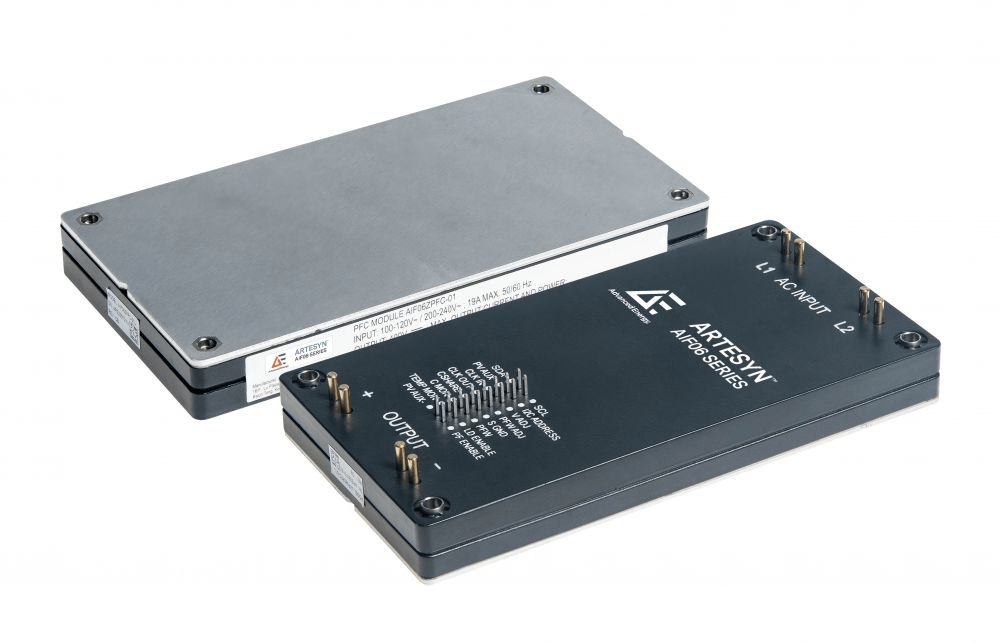

Convertidor PFC de bloque completo Advanced Energy AIF06ZPFC-01L, 2400 W (230 V CA) / 1400 W (115 V CA), salida de 400 V CC, entrada de 85-264 V CA, 6 A — Serie AIF06

Precio habitual

$750.00 USD

Precio habitual

Precio de oferta

$750.00 USD

Los gastos de envío se calculan en la pantalla de pago.

Cantidad

No se pudo cargar la disponibilidad de retiro

Secure checkout via Credit Cards, PayPal & Bank Wire (T/T)

Descripción general: El AIF06ZPFC-01L de Advanced Energy es un convertidor de corrección del factor de potencia (PFC) de bloque completo sin aislamiento, optimizado para sistemas de alimentación industriales y médicos de alta densidad. El módulo admite una amplia entrada de CA universal (85–264 V CA), proporciona una salida nominal de 400 V CC y suministra hasta 2400 W continuos en línea alta. Ofrece una alta eficiencia de conversión y comunicaciones PMBus para un control y una monitorización avanzados.

Especificaciones clave

- Modelo: AIF06ZPFC-01L (serie AIF06)

- Voltaje de entrada: 85–264 V CA (50/60 Hz)

- Tensión de salida nominal: 400 Vcc (típica)

- Potencia/corriente de salida nominal:

- Línea alta (Vin ≥ 200 V CA): 2400 W, Iout = 6,0 A

- Rango medio (180 ≤ Vin < 200 Vac): 2200 W, Iout = 5,5 A

- Línea baja (Vin < 180 V CA): 1400 W, Iout = 3,5 A

- Eficiencia: 97% típica (carga completa a 230 V CA)

- Factor de potencia: 0,99 típico (Po > 1400 W); 0,97 típico (Po > 700 W)

- Entrada/sobretensión: Resistencia a sobretensiones de entrada: 290 V CA/1 s; corriente de sobretensión máxima: 17,5 A durante 1 ms

- Protección contra sobretensión: 450 Vdc máx.

- Protección contra sobretemperatura (placa base): 110 °C máx.

- Protección contra sobrecorriente (típica): 4,2 A a 115 V CA; 7,2 A a 230 V CA (OCP con enclavamiento a 230 V CA)

- Capacitancia de salida: hasta 2000 µF por módulo

- Salida auxiliar: 11–13 V a 20 mA

- Comunicación/Control: compatible con PMBus®; CLK_IN/CLK_OUT 280 kHz ±5%; compatible con TTL/CMOS; habilitación de PFC; habilitación de LD mediante optoaislador; V_ADJ ajustable 330–400 V (configurado con resistencia de 0,1%)

- Factor de forma/mecánico: Contorno estándar de bloque completo: 2,4" x 4,6" (~61,0 x 116,8 mm), altura 0,55" (densidad de potencia ~395 W/in³)

- Montaje: Placa base optimizada para refrigeración por contacto o montaje de disipador de calor; insertos roscados (esta versión -01L)

- Temperatura/altitud de funcionamiento: Arranque: -40 °C; Funcionamiento hasta -25 °C; temperatura máxima operativa en la placa base: 100 °C; altitud operativa hasta 4000 m (según IEC62368-1)

- Seguridad/cumplimiento: UL 62368-1, CSA C22.2 n.º 62368-1, CE EN62368-1; RoHS‑6; materiales UL94 V‑0

- Peso: típico 266 g (9,4 oz), máximo 320 g (11,3 oz)

- Garantía: Estándar de dos años (consulte con la fábrica para conocer plazos ampliados)

- Plazo de entrega: 14 días (según lo previsto)

Características y beneficios

- Alta densidad de potencia continua (2400 W en línea alta) en paquete estándar de bloque completo para diseños de sistemas compactos.

- La eficiencia ultra alta (≈97%) reduce la carga térmica y los requisitos de refrigeración.

- El amplio rango de entrada (85–264 VCA) permite una implementación global sin transformadores de entrada.

- Interfaz PMBus y controles programables para operación en paralelo, cambio de fase, compartición de corriente y monitoreo a nivel de sistema.

- Placa base diseñada para disipador de calor directo o enfriamiento por contacto para una integración térmica simplificada.

- La capacidad de arranque con pre-polarización y el límite de entrada interno (versión 01) simplifican el diseño del sistema y el comportamiento de arranque en frío.

- Funciones de protección robustas: OCP, OVP, OTP y capacidad de sobretensión definida.

Aplicaciones

- Rieles de alimentación para equipos semiconductores

- Fuentes de alimentación y variadores industriales

- Sistemas de energía médica (cumplen con las normas de seguridad aplicables)

- Etapas PFC de front-end de centros de datos y telecomunicaciones

- Cualquier aplicación de bus de CC de alta densidad que requiera una fuente de alimentación no aislada nominal de 400 V

Aspectos destacados de Pin & Control

- Pines de entrada L1/L2, pines de salida +/− por asignación de pines de bloque completo (consulte la asignación mecánica/de pines de la hoja de datos)

- Líneas PMBus/I²C (SDA/SCL), CLK_IN/CLK_OUT para sincronización, V_ADJ, CMON y pines de control de habilitación/deshabilitación provistos para la integración del sistema.

Qué incluye / Notas

- Solo módulo (disipador, diodos externos para >2 módulos en paralelo no incluidos).

- Para módulos en paralelo >2, se requieren diodos externos; para compartir 2 unidades, no se requieren diodos externos según la hoja de datos.

- Consulte con los ingenieros de fábrica/aplicación para obtener configuraciones PMBus personalizadas, configuraciones paralelas más allá de las recomendaciones de la hoja de datos y para obtener opciones de garantía extendida.

Compartir