1

/

von

1

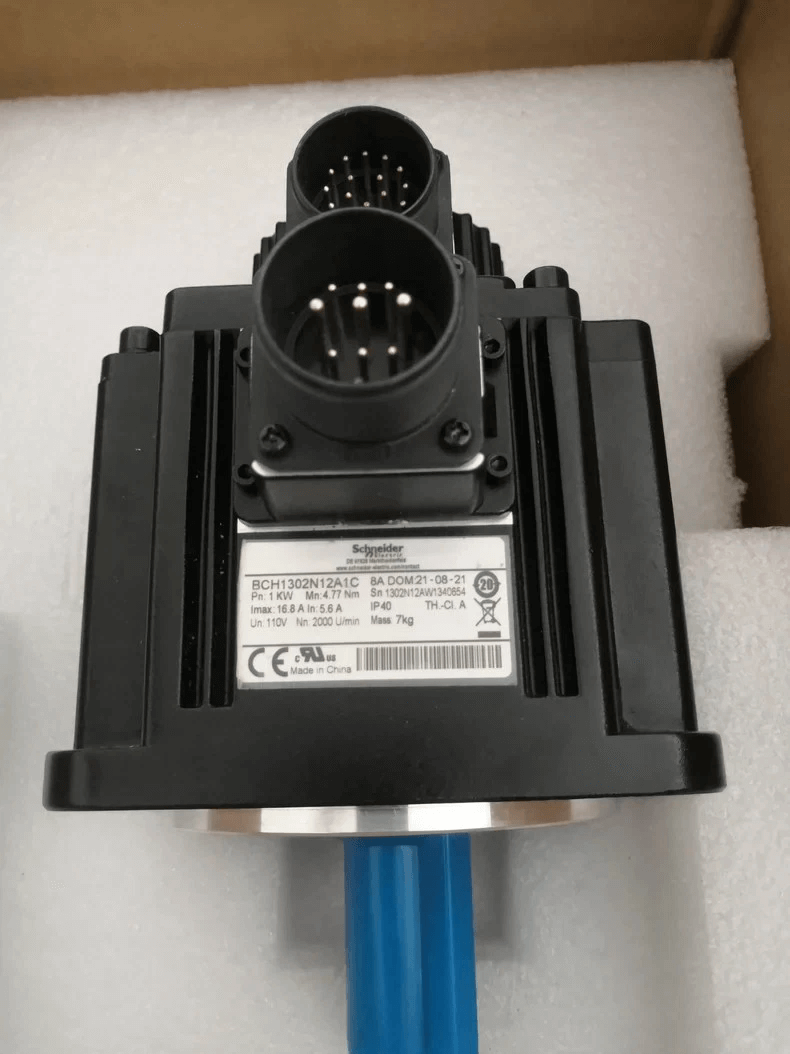

Schneider Electric BCH1302N12A1C BCH Series Servo Motor — Keyed Shaft, No Oil Seal, 20‑bit Encoder, No Brake, Straight Connector

Schneider Electric BCH1302N12A1C BCH Series Servo Motor — Keyed Shaft, No Oil Seal, 20‑bit Encoder, No Brake, Straight Connector

Normaler Preis

$325.00 USD

Normaler Preis

Verkaufspreis

$325.00 USD

Versand wird beim Checkout berechnet

Anzahl

Verfügbarkeit für Abholungen konnte nicht geladen werden

Secure checkout via Stripe & PayPal

Product overview The Schneider Electric BCH1302N12A1C is a BCH series industrial servo motor designed for precise closed‑loop motion applications. This variant features a keyed shaft (for positive torque transmission), no oil seal (suitable where contamination control or specific environmental sealing is not required), a high‑resolution 20‑bit encoder for accurate position feedback, no integrated brake, and a straight connector for power/feedback cabling.

Key features

- Manufacturer: Schneider Electric

- Model: BCH1302N12A1C (BCH series)

- Shaft: Keyed shaft (standard keyway for secure coupling)

- Sealing: No oil seal (open shaft design)

- Feedback: 20‑bit encoder providing high-resolution position feedback (digital encoder)

- Brake: Without integrated brake (motor supplied without holding brake)

- Connector: Straight connector configuration for motor power and encoder cabling

- Form factor: Industrial servo motor designed for machine‑tool, robotics and OEM motion systems

Benefits

- High position resolution from the 20‑bit encoder supports precise positioning and smooth motion profiles.

- Keyed shaft enables robust mechanical coupling for transmiting torque to gears, pulleys or encoders.

- Straight connector simplifies routing in many machine layouts and facilitates standardized cable assemblies.

- No integrated brake reduces mass and simplifies installation where holding torque is provided externally or not required.

- BCH family compatibility ensures straightforward integration with matching drives and feedback interfaces in Schneider Electric ecosystems.

Typical applications

- Robotics and pick‑and‑place axes

- Packaging, labeling and material handling equipment

- Indexing tables and rotary actuators

- OEM automation systems requiring high‑resolution feedback and secure shaft coupling

Installation and compatibility notes

- Confirm electrical and mechanical compatibility (voltage, current, rated torque, mounting dimensions and connector pinout) with the target drive/controller and machine design before installation.

- As this variant has no oil seal and no brake, evaluate environmental exposure and holding requirements; add external sealing or brakes where necessary.

- Use Schneider Electric documentation for connector pinouts, encoder wiring, mounting dimensions and recommended torque limits for the keyed shaft.

- Follow manufacturer installation, grounding and EMC guidelines to ensure reliable operation and long service life.

Documentation and support

- Refer to the official Schneider Electric BCH series datasheet and user manual for full electrical ratings, mechanical dimensions, encoder protocol details, wiring diagrams and maintenance instructions.

Share